UNITED VAN DER HORST LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to UNITED VAN DER HORST LTD.

Piston Crowns

United Van Der Horst has successfully combined specialized welding technology and Hard Chrome plating techniques for the complete reconditioning of damaged or worn Piston Crowns. All ring grooves are built to standard size, top and bottom faces of grooves are chrome plated to reduce wear. Thee entire procedure are approved by classification societies like IRS, DNV, BV, Lloyds. Testing of final products is witnessed band certified by the respective classification society.

Cylinder Covers

All burnt areas in the combustion bowl and internal cracks are successfully rebuilt by machining out worn-out / damaged areas prior to weld build up. DP checks are carried out intermittently all through the process of reconditioning. The latest modification are implemented as per manufacture's recommendation. Third party inspection and certification is carried out by agencies like IRS, BV, DNV, Lloyds, etc.

Exhaust Valves Spindles

All worn-out / damaged base material is removed till sound metal by machining. The valve is then welded by compatible electrodes and inlaid with satellite and machined to original dimensions and profiles. Stem is built up to standard dimensions by Hard Chrome plating, if required.

Exhaust Valve Seats

These are reconditioned by removal of worn-out / damaged portions are pre-machined to sound metal. NDT checks are performed prior to weld built up. Inlay of satellite on valve seat area and finish machining followed by lapping and blue matching with respective valve spindle is done to ensure minimum 70% contact area.

Cylinder Heads

All burnt areas in the combustion bowl and internal cracks are successfully rebuilt by machining out worn-out / damaged areas prior to weld build up. DP checks are carried out intermittently all through the process of reconditioning. The latest modification are implemented as per manufacture's recommendation. Third party inspection and certification is carried out by agencies like IRS, BV, DNV, Llyods etc.

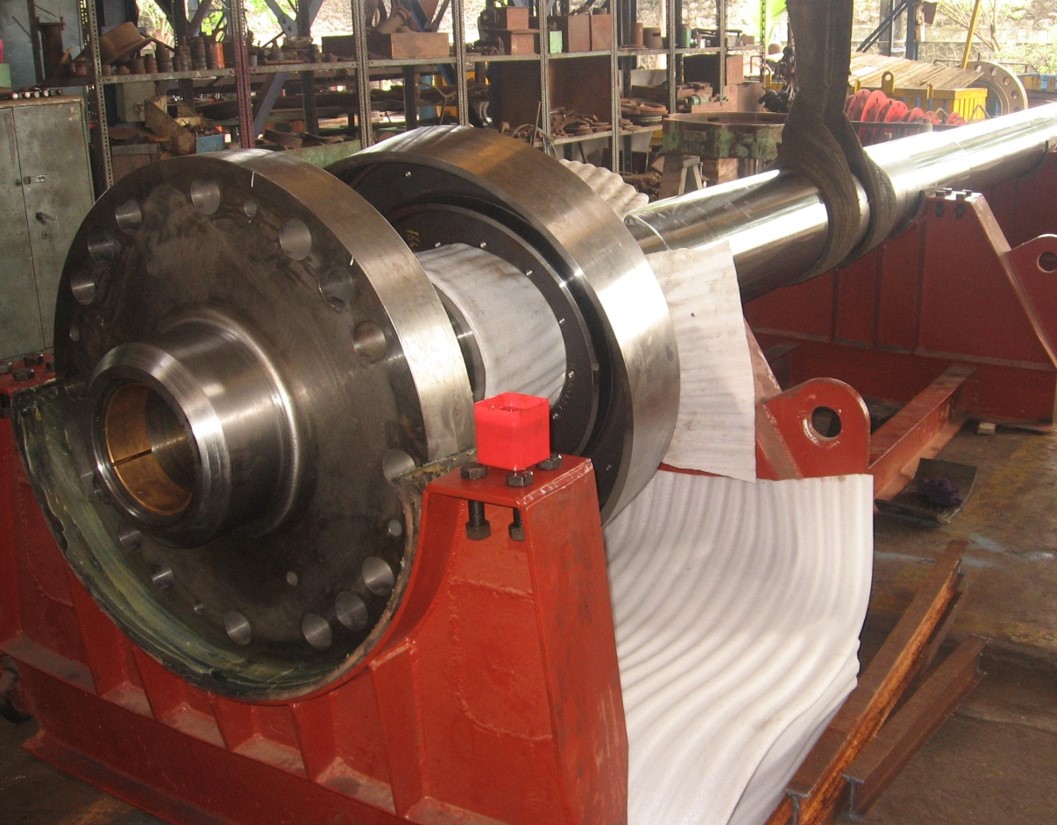

Crankshaft

Re-conditioning of crank shaft up to 10 meters long with a swing over a diameter of 1.2 meters. Repairing of crankpins and main Journals by juxtaposing the grinding process. Services for crank-shaft also includes straightening of crankshaft by peening method, full dimensional inspection in addition with magnaflux crack detection. The entire procedure are approved by classification societies like IRS, DNV, BV, Lloyds. Inspection of final product is witnessed and certified by the respective classification society.

Hydraulic Cylinders

Cylinders are manufactured / reconditioned, inspected and tested in accordance with "ISO 10100:2001 : Hydraulic fluid power Cylinders-Acceptance tests". Please refer to our hydraulic cylinder catalog for details complete solution including custom made new cylinders and reconditioning of worn out or damaged cylinders like hatch covers, grabs, crane booms, reach stacker cylinders, dry dock gates cylinders, lift, boom, tilt, steering, outrigger jack cylinders etc. Modified seals with latest technology and with modified sealing profiles are available.

Special fittings tools can also be supplied to prevent damage to the seals while installation and for ease of fitment. The cylinders are coated with special anti-corrosive epoxy paints or suitable surface treatments is carried out based on environment of service.

Rudder Stock

Rudder stock is a part of Rudder system of Ships for directional control. Repair scope includes rectification of damaged / pitted surface of rudder stock as per approved WPS (welding procedure specification) from DNV / Approved certifying authority for the respective ship. High stress concentrated areas shall be taken in to consideration during welding.

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.